INVESTIGATION REPORT Pesticide Chemical Runaway Reaction Pressure Vessel Explosion (en Inglés)

Reseña del libro "INVESTIGATION REPORT Pesticide Chemical Runaway Reaction Pressure Vessel Explosion (en Inglés)"

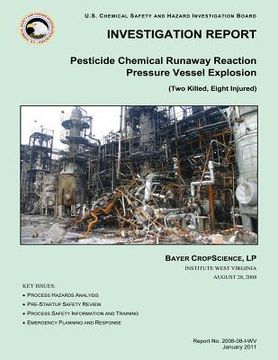

On August 28, 2008, at about 10:35 p.m., a runaway chemical reaction occurred inside a 4,500 gallon pressure vessel known as a residue treater, causing the vessel to explode violently in the methomyl unit at the Bayer CropScience facility in Institute, West Virginia. Highly flammable solvent sprayed from the vessel and immediately ignited, causing an intense fire that burned for more than 4 hours. The fire was contained inside the Methomyl-Larvin insecticide unit by the Bayer CropScience fire brigade with mutual aid assistance from local volunteer and municipal fire departments. The incident occurred during the restart of the methomyl unit after an extended outage to upgrade the control system and replace the original residue treater vessel. Two company employees who had been dispatched by the control room personnel to investigate why the residue treater pressure was increasing were near the residue treater when it ruptured. One died from blunt force trauma and burn injuries sustained at the scene; the second died 41 days later at the Western Pennsylvania Burn Center in Pittsburgh, Pennsylvania. Six volunteer firefighters who assisted in the unit fire suppression activities and two contractors working at the facility were treated for possible toxic chemical exposure. The Kanawha-Putnam County Emergency Management Director advised more than 40,000 residents, including the resident students at the West Virginia State University adjacent to the facility, to shelter-in-place for more than three hours as a precaution. The fire and drifting smoke forced the state police and local law enforcement authorities to close roads near the facility and the interstate highway, which disrupted traffic for hours. The Chemical Safety Board (CSB) investigation team determined that the runaway chemical reaction and loss of containment of the flammable and toxic chemicals resulted from deviation from the written start-up procedures, including bypassing critical safety devices intended to prevent such a condition. Other contributing factors included an inadequate pre-startup safety review; inadequate 1 operator training on the newly installed control system; unevaluated temporary changes, malfunctioning or missing equipment, misaligned valves, and bypassed critical safety devices; and insufficient technical expertise available in the control room during the restart. Poor communications during the emergency between the Bayer CropScience incident command and the local emergency response agency confused emergency response organizations and delayed public announcements on actions that should be taken to minimize exposure risk. Although Bayer CropScience reported that "no toxic chemicals were released because they were consumed in the intense fires," the CSB later confirmed that the only air monitors suitably placed near the unit to detect toxic chemicals were, in fact, not operational at the time of the incident. No reliable data or analytical methods were available to determine what chemicals were released, or predict any exposure concentrations. The methomyl unit used the highly toxic chemical, methyl isocyanate (MIC), in a series of complex chemical reactions to produce methomyl, a dry chemical used to make the pesticide, Larvin. MIC is manufactured in a separate production unit at the facility and stored in large underground pressure vessels. Liquid MIC was pumped to a "day tank" pressure vessel near the Methomyl-Larvin unit, which provided the daily production quantity of MIC for the methomyl unit and the carbofuran unit, which is about 200 feet west of the methomyl unit. The MIC storage tank adjacent to the methomyl unit and the MIC transfer piping between the production unit and the manufacturing units were not damaged, nor did the MIC storage tank overheat or pressurize above the operating limits during the fire.